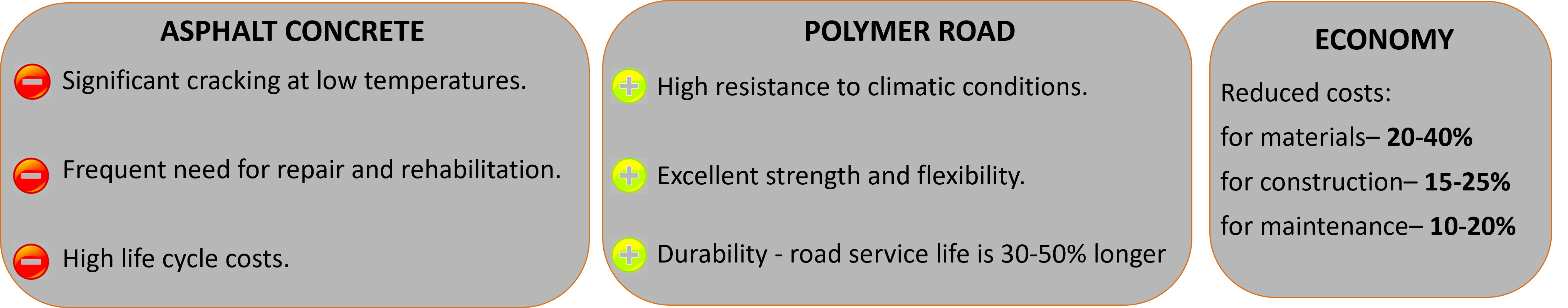

Modern asphalt pavement, faces a number of challenges:

1) Deformations and failures (rutting, cracks, potholes).

2)

Influence of weather conditions (temperature variations, water and frost, UV radiation).

3) Intensive exploitation.

4) High cost of maintenance.