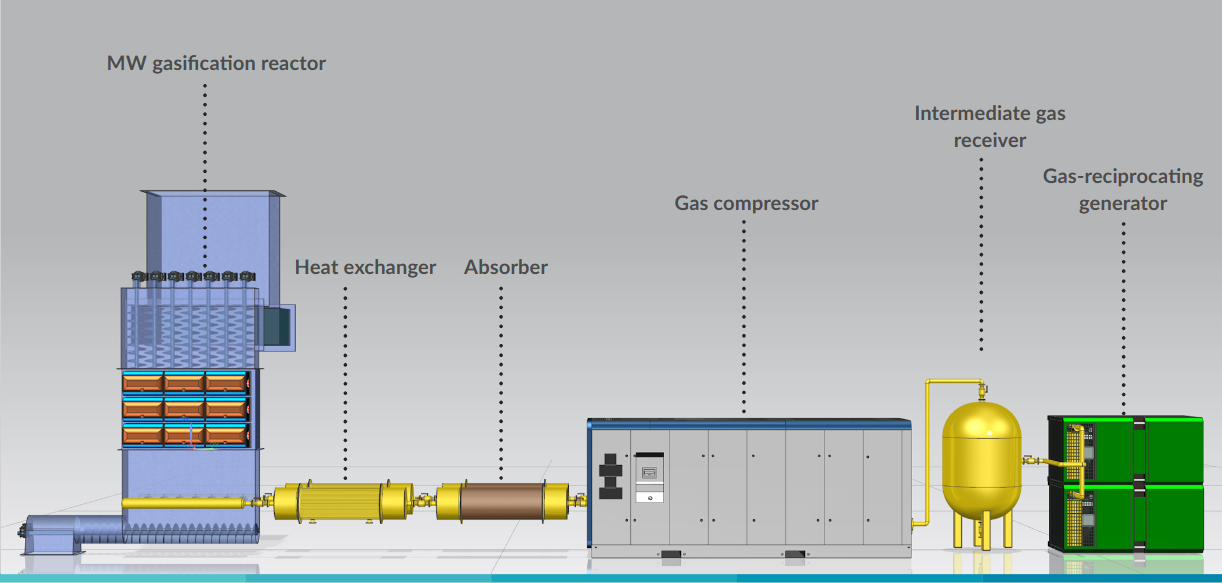

Neutralisation and disposal of waste by means of MW MATRIX microwave irradiation.

The microwave units are capable of disposing of waste of hazard classes I to V with subsequent gas synthesis.

The material is heated throughout its entire volume, irrespective of its composition

Depending on the type of waste, air or inert gases can be fed into the chamber

The process takes place in a controlled environment (with excess or shortage of gases)

The unit can operate as a pure gasifier

The temperature of the working chamber walls is lower than the temperature of the waste to be disposed of, which completely eliminates the negative processes of coal slag deposition on the walls of the working chamber